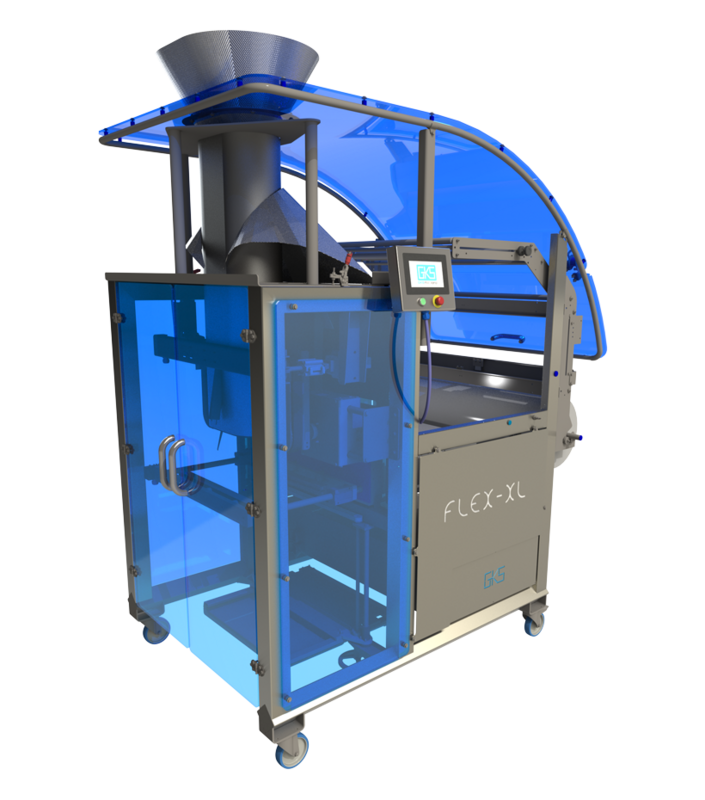

GKS FLEX-XL

Machine is standard equipped with:

Stainless steel construction; hygienic design. Machine safety according to CE regulations. Allen Bradley PLC with 7” full colour touchscreen and 99 programs can be created and stored. Photocell for bag length detection with pre-printed film. End of film detection. Pneumatic opening and closing of the servo driven film pull belts. Ergonomic film support with pull off mechanism, film tensioning and brake. Low power and air consumption. Cover plate over the entire machine. Machine in mobile frame.

Options: FLEX-XL

QC-Seal system (LDPE, PP + Laminated films)

Air cooling on sealing system

Handgrip sealing system

Block bottom/gusset mechanism

Lateral film guiding system

Film splice table

Vibration unit

Bag support system

Connection for gas flushing (MAP)

Vacuum system

Perforation systems

Printing and labelling systems

Various weighing and dosing systems

Customer specific options on request

Technical specifications FLEX-XL:

Bag width (pillow) 200 – 500 mm

Max. bag length unlimited mm

Max. bag length per sealing step 480 mm

Max. production speed 20 bags/min

Film thickness 25 – 120 μ

Core diameter 76 (3”) mm

Max. film width 1.050 mm

Max. outer diameter film roll 320 mm

Voltage 230 V, 50/60Hz

Power during production 1.600 Watt

Air consumption 6 bar, 200 ltr/min

All dimensions and specifications are indications based on standard set up. Final details depend on customer specifications

• Stainless steel; hygienic design

• Robust build quality

• Modular construction

• Allen Bradley PLC and electrical components

• Servo driven film transport for accurate bag length

• Ergonomic film support with pull off mechanism, film tensioning and brake