Optimum NOVUS

The NOVUS Optical Sorting System is available in different sizes. Its maximum scanning width of 2400 mm makes it the widest optical belt sorter on the market. The NOVUS may be used on a stream of fresh, dried or frozen potato products, fruit and vegetables, crustaceans and shellfish, confectionery and nuts.

Six-sided camera inspection

Depending on the scanning width and the application, the NOVUS is standardly equipped with 3, 6 or 9 advanced high-resolution cameras that accurately detect discoloration, size and shape deviations. A unique camera configuration was developed especially for the sorting of diced potatoes and other tuberous vegetables, in which the cameras are arranged in such a way that five of the six sides of each cube are always shown perpendicularly. And there is more: the innovative S-TEC module also inspects the bottom of the product, which is particularly interesting for dry products such as nuts and confectionery.

Multispectral laser detection

To further increase its sorting accuracy, the NOVUS may be equipped with up to 8 lasers (and 16 laser detectors). Thanks to the combination of different lasers with specific wavelengths, it easily detects structure and biological characteristics. Structure sorting is ideally suited for detecting foreign objects, such as wood, plastic, stone, glass and metal. SWIR (Short Wave Infrared) lasers see the difference between aqueous and non-aqueous products, which is also ideal for finding foreign objects between fruit and vegetables. Special fluorescent lasers in turn detect the chlorophyll content of green vegetables or the presence of harmful substances, such as solanine in potatoes and other tuberous vegetables. The right combination of lasers even detects the almost invisible sugar ends on raw French fries.

Superior resolution

The NOVUS Optical Sorting System has an impressive laser scanning speed of up to 4000 scans per second, resulting in an optical resolution of 0.3 mm, the highest resolution of any laser sorter on the market. It can therefore easily detect the smallest impurities such as thin wood splinters in frozen vegetables, shell fragments in nuts, and even glass splinters. The NOVUS may be used for many different applications: fresh, dried or frozen potato products, fruit and vegetables, crustaceans and shellfish, confectionery and nuts.

Metal detection

The M-TEC module built into the frame detects and removes tiny stainless steel, ferrous and non-ferrous metal particles that the cameras and lasers might possibly not detect because they are hidden under the product on the sorting belt or in the product itself. The module is made up of several smaller detector coils, which means that its detection sensitivity is much more effective than that of traditional metal detectors.

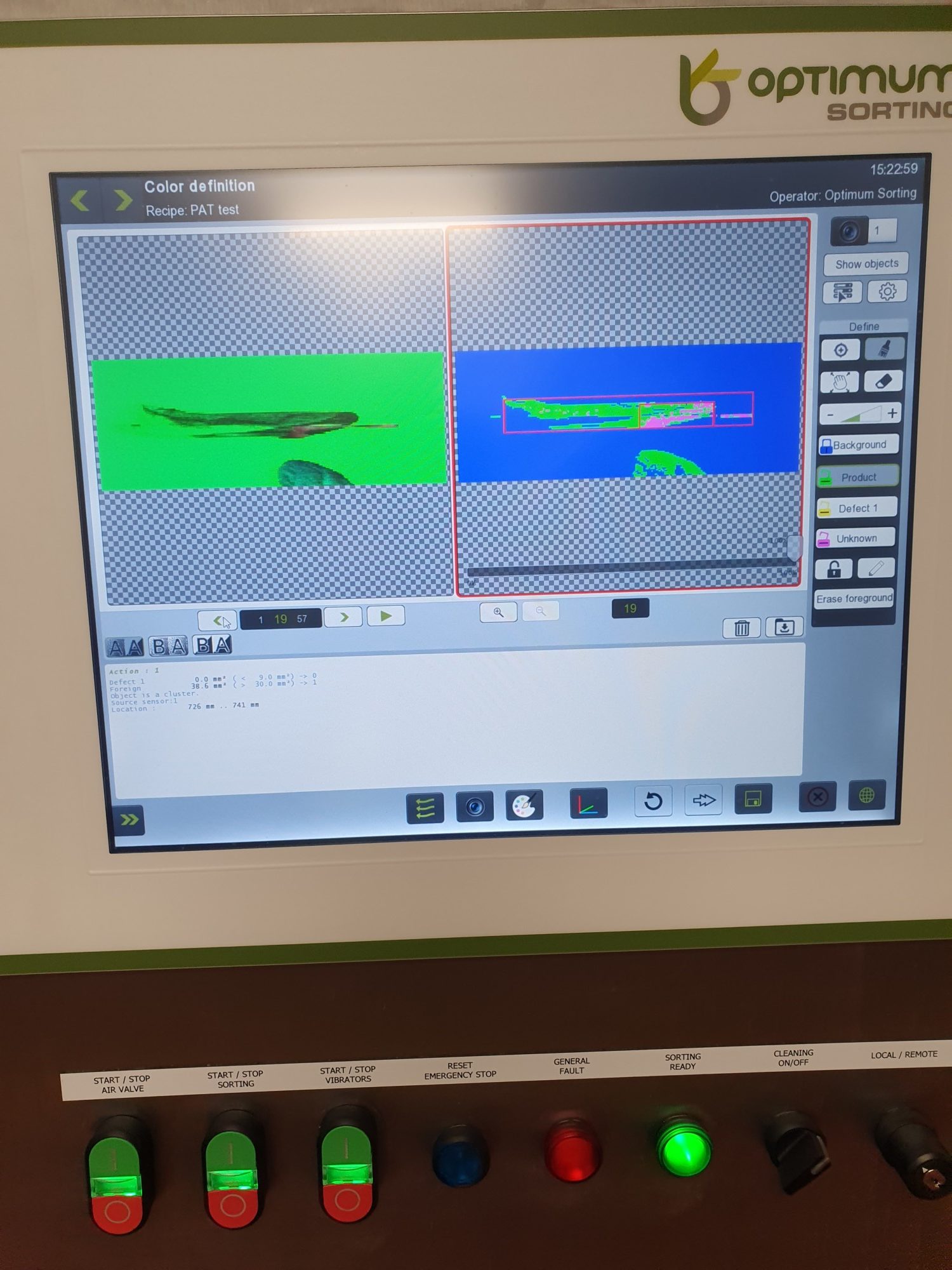

Multidimensional image processing

The different camera and laser signals are processed simultaneously so that defects and foreign objects are detected more accurately and the risk of erroneous rejections is reduced. The result: an excellent good-to-bad ratio that leaves other systems behind. Artificial intelligence The NOVUS is able to differentiate multiple product & defect classes and, if necessary, process them differently. Its advanced sorting software uses AI (artificial intelligence): it learns to identify products & defects on the basis of images of the objects passing through the machine. During the sorting process, the algorithm autonomously decides which products are removed. If your operators still detect errors, they can easily adjust the algorithm.

Precision ejection system

Defective products are removed from the flow of good products using compressed air. Using an optional second ejection mechanism, you may also apply three-way sorting in addition to two-way. In order to get an excellent good-to-bad ratio even for the smallest products, the NOVUS may be equipped with a high-density valve system: ultra-fast and small ejection valves with a center-to-center distance of 4.6 mm.

Optimal hygiene, flexibility and integrability

The design of the base frame of the NOVUS meets the strictest hygiene standards and machine guidelines. Moreover, it’s modular, so that the NOVUS cannot only be easily configured according to your needs, but can also be expanded with the same flexibility after installation. And finally, its operating and sorting software uses the CUMULUS platform, just like all our other machines. Integrability guaranteed.

ENQUIRE ONLINE01449 771 202- widest optical belt sorter

- excellent good-to-bad ratio

- unique three-in-one combination of camera, laser and metal detection

- sorting on the basis of color, shape, structure and biological and magnetic properties

- superior resolution

- advanced sorting software using AI

- optimal flexibility and integration options

- perfect hygiene

- fast product switching

- 24/7 (remote) service